About Polaris Coaster

Design

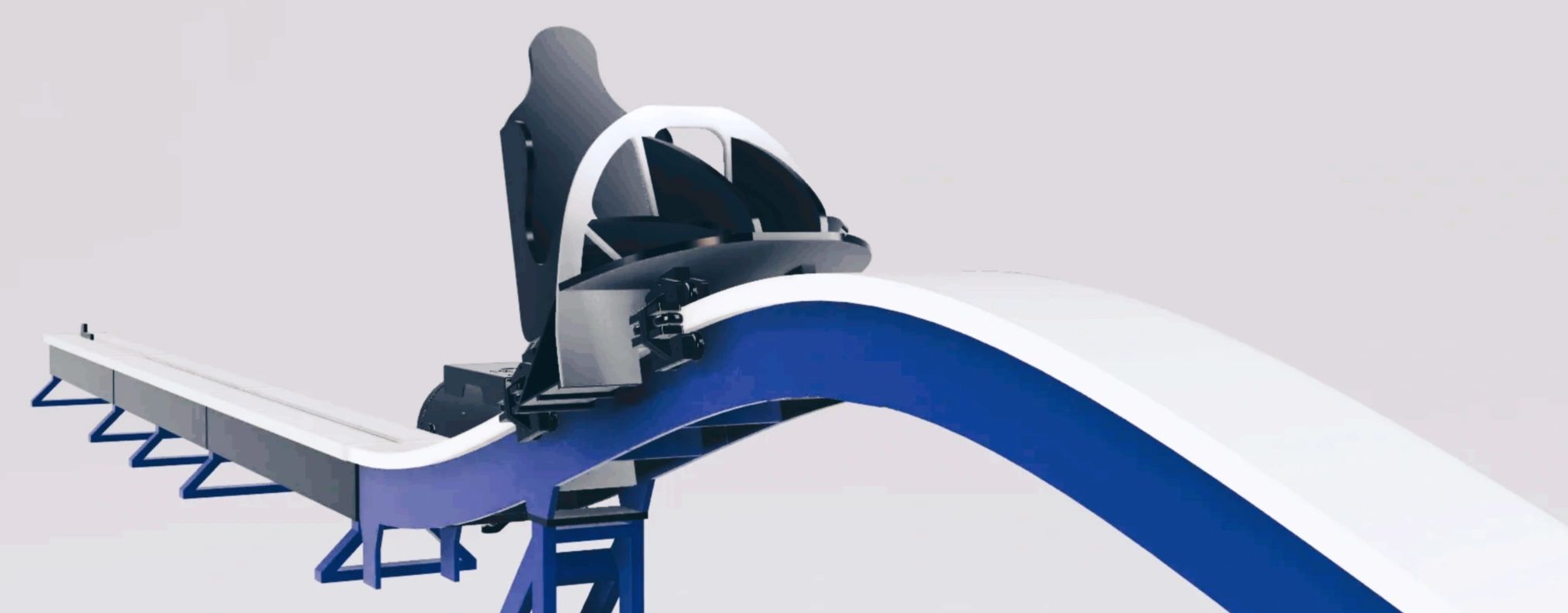

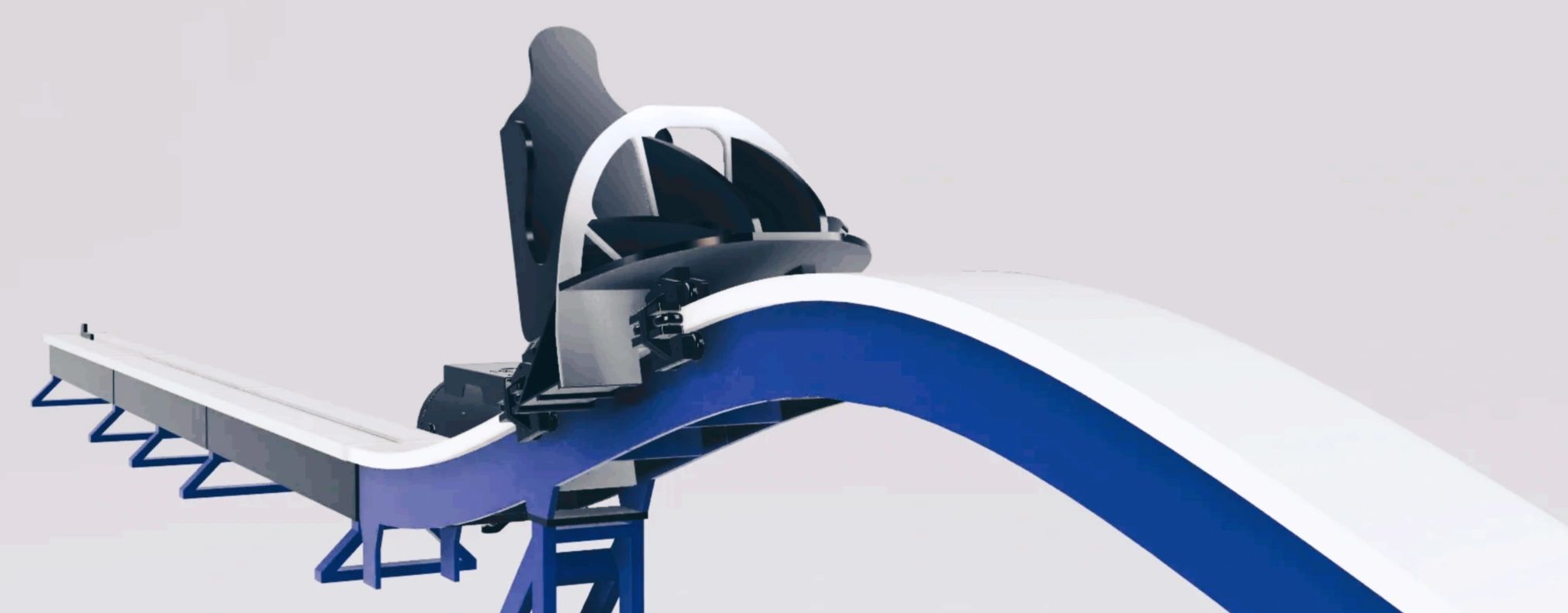

The entirety of Polaris was first modeled in NoLimits2 and exported into Fusion360 to be rendered in CAD, allowing for easier fabrication. While inspiration was taken from several companies, every piece and aspect of the ride was custom designed. The entire design process of the ride took around 100 hours of work.

Fabrication

All sections of the ride were fabricated out of 3/4" marine-grade plywood using a ShopBot CNC for the precise curvature cuts to ensure a smooth ride. The two side pieces of track are the CNC sections, which are connected together with a square section of plywood in between them. A thin veneer was then placed on the top to act as a cover.

Chassis

The Polaris Chassis is modeled directly after the RMC Raptor trains, which utilize a single-across configuration, allowing for a very thin track guage of only 15.5 inches. This chassis is able to hold one passanger at a time, up to 200 lbs.

Launch System

Based off the compressed air launch pioneered by S&S, Polaris is able to generate over 1000 lbs of force almost instantaneously, allowing for an acceleration in excess of 3 G's. For further diagrams or explanation on this system, please contact me below.

Polaris in action

On-Ride POV

Off-Ride

Copyright © 2024 Polaris Coaster - All Rights Reserved.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.